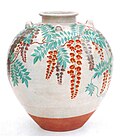

Iwami ware

Iwami ware (石見焼, Iwami-yaki) is a type of Japanese pottery traditionally from Shimane Prefecture.

Description

[edit]Origin

[edit]Iwami ware originated in the mid-18th century in the western part of Shimane Prefecture (the Iwami region).[1] It began when warriors returning from the Japanese invasions of Korea brought back a Korean potter to produce pottery.[1] "Shinozukuri," a traditional method unique to Iwami ware, emerged during this period, enabling the production of large ceramics.[2]

History

[edit]The evolution of Iwami ware spans centuries, marked by pivotal advancements in production techniques. In 1765, the introduction of authentic porcelain manufacturing methods enriched the pottery tradition in the region.[1] The 1780s witnessed a surge in ceramic production, including large-scale pieces like water jugs, influenced by artisans from Bizen province.[1] By the end of the Edo period, the Gotsu area emerged as a prominent hub for pottery production, particularly renowned for its exquisite water jugs.[1] During the Meiji period, mass production of large water jugs became prominent, showcasing the continuous evolution of Iwami ware.[1] Moreover, the unique method of "Shinozukuri" remained integral to the production process, allowing for the creation of various large-scale interior items beyond water jugs.[2]

Characteristics

[edit]Source:[1]

Iwami ware is celebrated for its durability, minimal water absorption, and resilience against salt, acid, and alkali. Its repertoire includes an array of products, from the iconic water jugs (handou) to everyday essentials such as tea utensils and tableware. Crafted from locally sourced, high-grade clay akin to porcelain, these pieces are adorned with either a rich, dark reddish-brown kimachi enamel or a transparent enamel derived from yunotsu stone. The firing process imbues them with distinctive hues; oxidized firing renders ochre tones, while reduction firing produces captivating blues.

Production Process

[edit]- Mixing clay and allowing it to dry for six months or more.[3]

- Dehydrating levigated clay to eliminate impurities.[3]

- Chrysanthemum kneading to expel air bubbles and ensure uniform moisture distribution.[3]

- Molding on the lathe, by hand, or employing slab techniques.[1]

- Drying the molded pieces thoroughly.[3]

- Bisque firing at approximately 800 °C.[1]

- Applying selected enamel glaze.[1]

- Dipping smaller ceramic pieces into the enamel solution.[1]

- Loading pots into the kiln with precision.[3]

- Firing at high temperatures ranging from 1250 °C to 1280 °C, resulting in robust, beautifully finished pottery.[1]

References

[edit]External links

[edit]